Are Ceramic Cutting Boards Good?

The kitchen cutting board landscape has evolved dramatically beyond traditional wood and plastic options, with ceramic emerging as a sophisticated alternative that challenges conventional wisdom about food preparation surfaces. Ceramic cutting boards represent a paradigm shift toward hygiene-focused, aesthetically pleasing kitchen tools that serve dual purposes as functional prep surfaces and elegant serving platforms.

However, the question of whether ceramic cutting boards are genuinely "good" depends heavily on understanding their unique properties, limitations, and optimal use cases. Unlike their wooden or plastic counterparts, cutting boards made from ceramic operate under completely different performance parameters that can either enhance or hinder your culinary workflow.

The Science Behind Ceramic Cutting Surfaces

Ceramic cutting boards are manufactured through high-temperature firing processes that create extremely dense, non-porous surfaces. This manufacturing approach results in boards that are naturally antibacterial, as harmful microorganisms cannot penetrate the smooth, sealed surface. The vitrification process eliminates the microscopic cracks and crevices that typically harbor bacteria in other cutting board materials.

The molecular structure of ceramic provides inherent advantages for food safety. Unlike wood, which can absorb juices and develop bacterial colonies over time, or plastic, which develops knife scarring that creates bacterial hiding spots, ceramic maintains its hygienic integrity throughout its lifespan. This fundamental difference makes ceramic cutting boards particularly valuable in professional kitchens and homes where food safety takes priority.

From a chemical standpoint, ceramic boards are completely inert and non-reactive. They won't absorb flavors, colors, or odors from strong ingredients like garlic, onions, or beets. This characteristic allows you to transition seamlessly between different food preparation tasks without cross-contamination concerns.

Knife Compatibility and Blade Preservation

The relationship between ceramic cutting boards and knife edges represents the most significant consideration for potential users. Ceramic surfaces are significantly harder than steel knife blades, which means extended use on ceramic boards will dull knives faster than softer cutting surfaces. This trade-off between hygiene benefits and knife maintenance requirements forms the central decision point for most home cooks.

However, the dulling effect varies considerably based on cutting technique and knife quality. Proper knife skills that emphasize slicing motions rather than chopping minimize blade contact with the board surface. Professional chefs who use ceramic boards often adjust their cutting techniques to preserve blade edges while capitalizing on ceramic's hygienic advantages.

Consider these factors when evaluating knife compatibility:

• Cutting technique adaptation - Slicing motions preserve blade edges better than chopping

• Knife quality impact - Higher-quality steel maintains sharpness longer on ceramic surfaces

• Sharpening frequency - Plan for more frequent knife maintenance when using ceramic boards regularly

• Task-specific usage - Reserve ceramic boards for specific prep tasks rather than all cutting activities

Maintenance and Cleaning Advantages

The non-porous nature of ceramic cutting boards makes them remarkably easy to clean and sanitize. Standard dishwashing with soap and hot water removes all surface contamination, while the smooth surface prevents bacterial growth between cleanings. This ease of maintenance represents a significant advantage for busy kitchens where thorough sanitization must happen quickly.

Unlike wooden boards that require periodic oiling or plastic boards that eventually need replacement due to scarring, ceramic boards maintain their original condition indefinitely with basic care. The durability and low maintenance requirements often offset the higher initial investment cost over the board's extended lifespan.

Cleaning protocols for ceramic boards are straightforward:

• Daily cleaning - Hot soapy water removes all surface residue and bacteria

• Deep sanitization - Diluted bleach solutions provide hospital-level sterilization when needed

• Dishwasher compatibility - Most ceramic boards handle dishwasher cycles without damage

• Stain resistance - Strong ingredients won't permanently discolor ceramic surfaces

Aesthetic and Functional Versatility

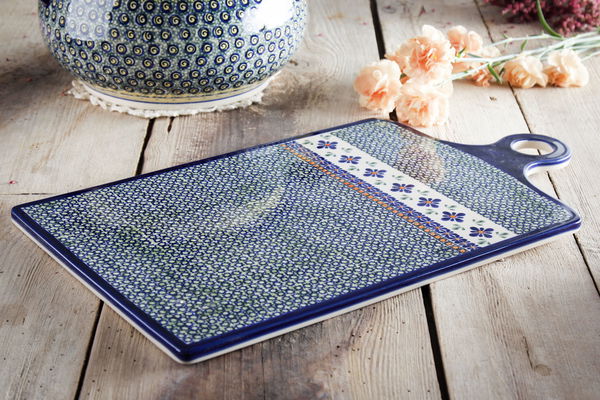

Beyond pure functionality, ceramic cutting boards serve double duty as attractive serving pieces that transition seamlessly from prep work to table presentation. The elegant appearance of quality ceramic boards eliminates the need for separate serving platters when presenting charcuterie, cheese selections, or sliced fruits.

This versatility proves particularly valuable in smaller kitchens where multi-purpose tools maximize limited storage space. A well-chosen ceramic cutting board can serve morning bread preparation, afternoon cheese service, and evening fruit presentation without requiring additional serving pieces.

The visual appeal extends to color and design options unavailable in traditional cutting board materials. Ceramic boards can incorporate decorative elements, varied textures, and custom colorations that complement specific kitchen aesthetics while maintaining full functionality.

Size and Thickness Considerations

Ceramic cutting board dimensions significantly impact both functionality and durability. Thicker boards provide more stability and resist flexing under pressure, but they also increase weight and storage requirements. The optimal thickness balances structural integrity with practical handling considerations.

Standard ceramic cutting boards range from 0.5 inches for lightweight models to 1.5 inches for commercial-grade options. Thicker boards handle heavy-duty tasks better but require more substantial storage solutions and careful handling due to increased weight.

Size selection should consider your primary use cases and available counter space. Larger boards accommodate bigger tasks but may overwhelm smaller kitchens, while compact boards offer easier handling at the expense of prep surface area.

Durability and Breakage Concerns

The durability question surrounding ceramic cutting boards centers on impact resistance rather than wear resistance. While ceramic boards resist scratching, staining, and bacterial growth indefinitely, they remain vulnerable to cracking or chipping if dropped or subjected to severe impact.

This characteristic requires different handling protocols compared to wooden or plastic boards. Ceramic boards demand respectful treatment and secure storage to prevent accidental damage. However, when handled appropriately, they often outlast multiple sets of traditional cutting boards.

Consider exploring our home collection to discover how ceramic durability translates across different household applications, from functional tools to decorative elements.

Cost-Benefit Analysis for Home Cooks

Initial investment costs for quality ceramic cutting boards typically exceed traditional alternatives, but the long-term value proposition often favors ceramic for dedicated home cooks. The combination of indefinite lifespan, minimal maintenance requirements, and dual-purpose functionality creates compelling economic arguments.

Factor in the hygiene benefits for families with immune-compromised members or those who prioritize food safety. The ability to achieve complete sanitization without harsh chemicals or complex procedures adds value that extends beyond simple economics.

However, casual cooks who rarely engage in extensive food preparation might find the investment disproportionate to their usage patterns. Honest evaluation of your cooking frequency and food safety priorities should guide the investment decision.

Specialized Applications and Niche Uses

Ceramic cutting boards excel in specific culinary applications where their unique properties provide distinct advantages. Pastry preparation benefits significantly from ceramic's cool, smooth surface that won't warm butter or other temperature-sensitive ingredients. The non-stick qualities help with delicate dough work and chocolate preparation.

For those interested in expanding ceramic functionality beyond the kitchen, our coffee-tea collection showcases how ceramic's thermal and aesthetic properties enhance beverage service and presentation.

Professional applications include:

• Sushi preparation - The smooth, sanitizable surface ideal for raw fish handling

• Chocolate work - Temperature stability prevents melting during tempering processes

• Herb processing - Easy cleaning prevents flavor cross-contamination

• Photography styling - Attractive boards serve as neutral backgrounds for food photography

Making the Right Decision for Your Kitchen

The determination of whether ceramic cutting boards are "good" depends entirely on matching their specific properties to your individual cooking style and priorities. Home cooks who prioritize hygiene, appreciate aesthetic versatility, and don't mind adjusting their knife maintenance routines often find ceramic boards transformative.

Conversely, cooks who rely heavily on chopping techniques, prefer traditional cutting board feel, or operate on tight budgets might find ceramic boards unnecessarily complex or expensive for their needs.

Conclusion: Understanding Your Cutting Board Priorities

Rather than declaring ceramic cutting boards universally good or bad, successful kitchen management involves understanding how different tools serve different purposes and user preferences. Ceramic boards represent a specialized tool that excels in specific applications while requiring accommodation in others.

The key lies in honest assessment of your food preparation habits, aesthetic preferences, and willingness to adapt established routines. Quality cutting boards of any material serve home cooks best when selected based on realistic usage patterns rather than idealized kitchen aspirations.

Validate your login

Sign In

Create New Account