Roasting pan large (2,2L)

$47.09

Out of stock

SKU

1158S1158P/SP-BR/1

| Diameter [cm] | 0.00 |

|---|---|

| Length [cm] | 31.30 |

| Weight [kg] | 3.350 |

| Capacity [liter] | 2.70 |

| Height [cm] | 19.20 |

| Width [cm] | 24.80 |

Roasting pan large (2,2L)• Ceramic roaster with a capacity of 2.2 litres

• The roaster is designed for baking and heating both savoury and sweet dishes

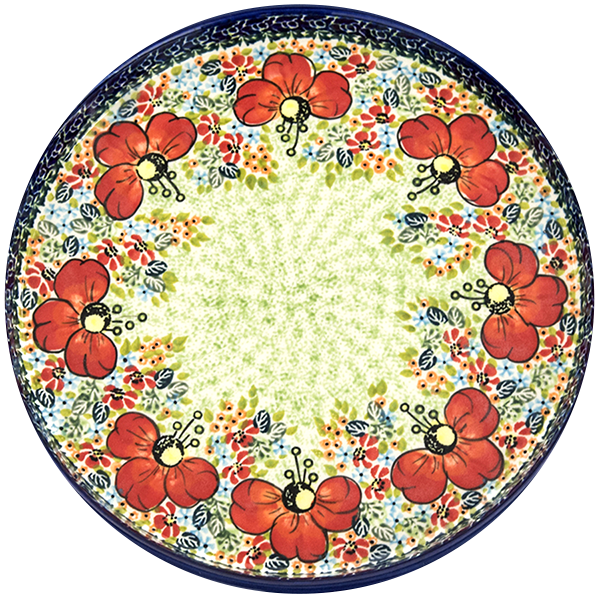

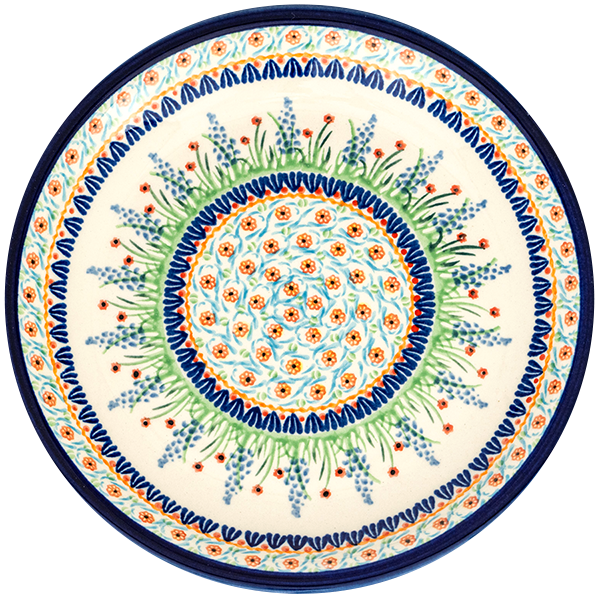

• The decorative character of the roaster makes it possible to use it also for serving food on the table

• The roaster is suitable for baking at temperatures up to 280 degrees Celsius in conventional ovens, microwave ovens, on glass ceramic hobs, on induction hobs and for storing food in a refrigerator

• The roaster is glazed and fired at a high temperature, which protects both the roaster and the decoration from damage

• Corrugated bottom supports the heat treatment process

• The roaster can be washed in the dishwasher, heated in the microwave and stored in the fridge.

• Thanks to the specific mass from which the roaster is made, it keeps food warm for a long time

• The traditional shape of the roaster will perfectly fit into a classically furnished kitchen, while in a modern kitchen it will be an intriguing addition

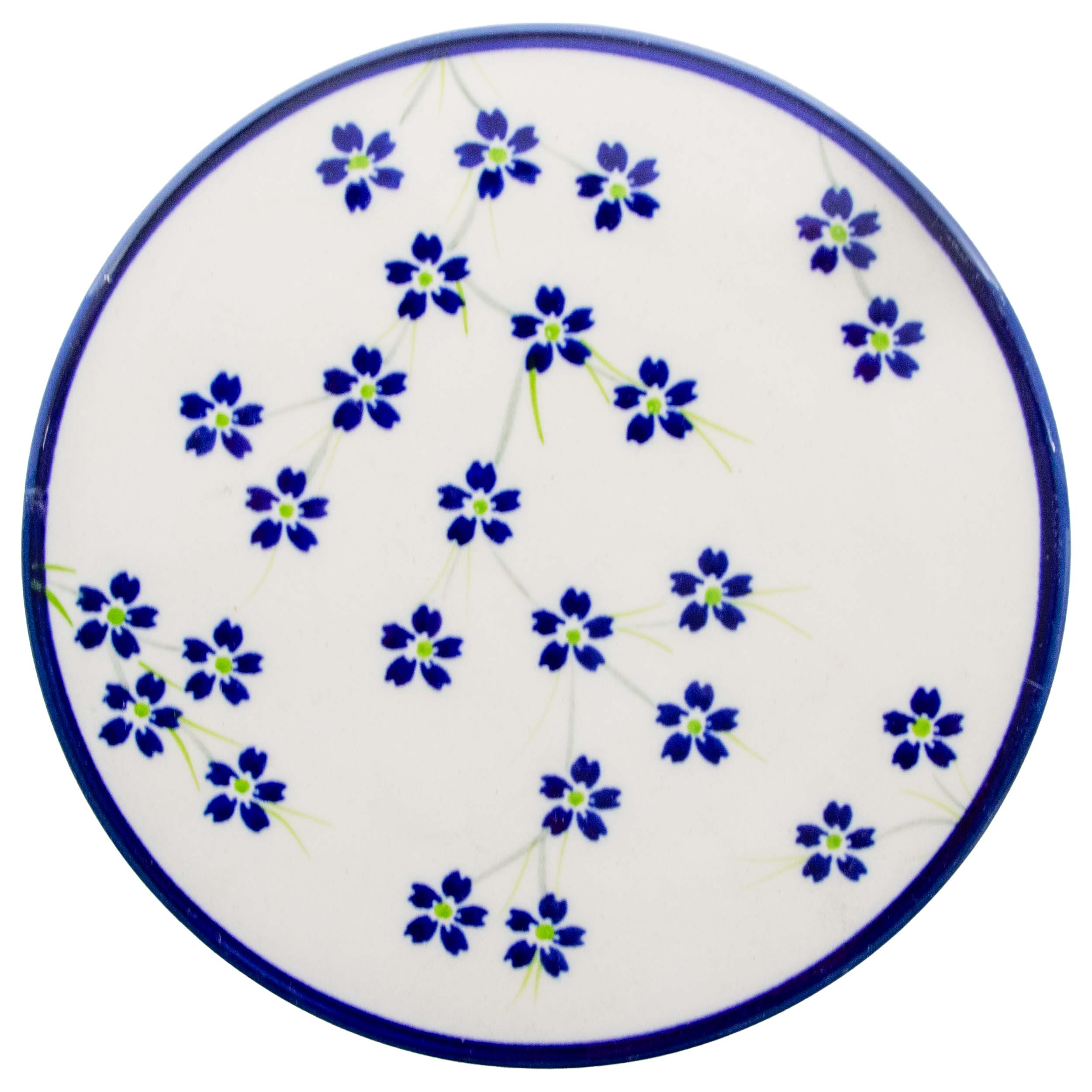

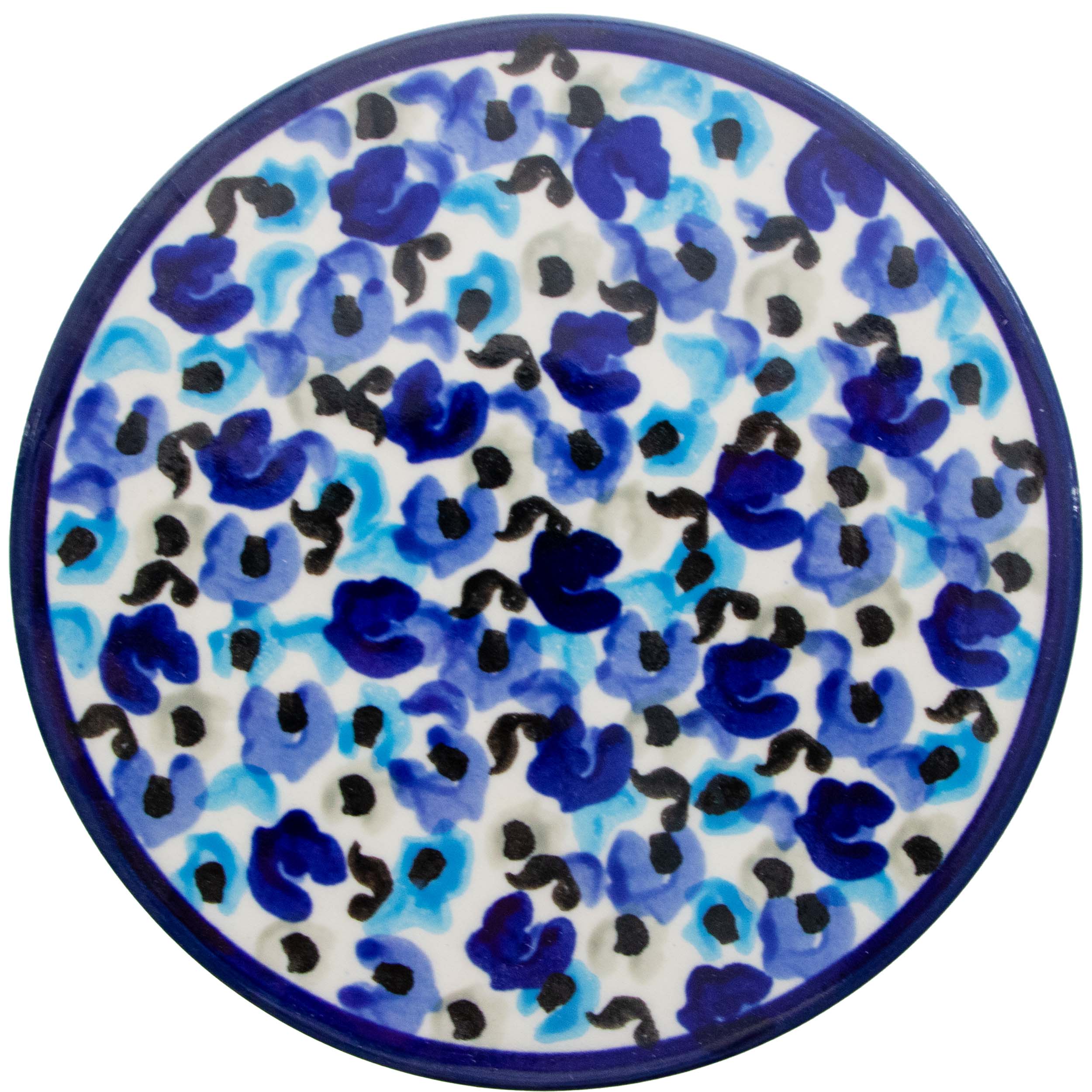

• Like the whole product range of Zakłady Ceramiczne "BOLESŁAWIEC", the roasters are also decorated manually, using stamps and brushes, thanks to which each one is unique and therefore minimal differences in decoration may occur between particular pieces within one decoration

Single-coloured glazesIn our offer you will find not only the pottery decorated with stamps and brushes, but also glazed in one colour. Since olive is sometimes a common colour in dinnerware decoration, plain, single-coloured dinnerware can be used to enlarge your own service set in an interesting way. For example, you can place plain dinner plates on the table, and on top of them soup plates or dessert plates decorated with a brush and stamps. Or the other way around.

All pottery from the offer of Zakłady Ceramiczne "BOLESŁAWIEC" are hand-made at each stage. In the case of single-colour glazed pottery, the first firing takes place, followed by manual glazing, and then a second firing at high temperature. Thanks to this sequence of activities each piece of pottery gains resistance to damage and colour change.